|

|

| Cuota De Producción: | 500kg |

| Precio: | Negotiation |

| Embalaje Estándar: | 25kg Carton+900kg/Pallet o 5KG/CTN |

| Período De Entrega: | 15days |

| Forma De Pago: | L/C, T/T, OA |

| Capacidad De Suministro: | 200Ton/month |

Cerradura de primavera de DIN127B M2 a las lavadoras de acero inoxidables grandes M100

Pues usted aprieta un perno, estas lavadoras métricas aplanan para añadir la tensión a la junta roscada y para evitar el aflojamiento de pequeñas cantidades de vibración. Todas estas lavadoras cumplen un estándar del estruendo o de ASME para las dimensiones partidas de la lavadora de cerradura.

Las lavadoras de cerradura partidas estándar tienen una hélice izquierda, que los medios usted pueden solamente utilizarlas con los pernos que tienen hilos derechos para prevenir la rotación a la derecha de la vibración. Cuando está apretado, su mordedura desigual de los extremos de fractura en nueces sin templar - y - pernos para un control más apretado que lavadoras curvado o de la onda, pero solamente para los usos con la rotación a la derecha. Las lavadoras, nueces, y los pernos serán deformados cuando están aflojados, así que ningunas de ellos pueden ser reutilizadas. No utilice estas lavadoras en superficies endurecidas.

Las lavadoras de acero inoxidables son más resistentes a la corrosión que de acero, y casi como fuertes. 18- 8 lavadoras de acero inoxidables son buenas para los ambientes húmedos, húmedos, y del baldeo, pero corroerán cuando están expuestas al agua salada y a otras soluciones del cloro. 316 lavadoras de acero inoxidables tienen la mejor resistencia a la corrosión. Hacen frente a ambientes mojados, apenas como 18-8 lavadoras de acero inoxidables, pero a diferencia del acero inoxidable 18-8, resisten la corrosión causada por el agua salada, las soluciones del cloro, y las sustancias químicas.

Utilice las lavadoras de acero cinc-plateadas cinc-plateadas y amarillas en sobre todo ambientes secos. La galjanoplastia del cinc ofrece la protección temporal del moho, pero una vez que lleva lejos el acero moho. Todas estas lavadoras son más fuertes y más desgaste - resistentes que el acero inoxidable.

Las lavadoras de acero son más fuertes y más desgaste - resistentes que el acero cinc-plateado y el acero inoxidable. Utilícelas en ambientes secos porque moho en ambientes mojados y corrosivos.

Materiales y compstition químico

| 化学成分 COMPOSI QUÍMICO (%) | ||||||||||

| Tipo | 碳 de C | 硅 del Si | 锰 del manganeso | 磷 de P | 硫 de S | 镍 del Ni | 铬 del Cr | 钼 del MES | 铜 del Cu | Otros |

| ≤ | ≤ | ≤ | ≤ | ≤ | ≥ | ≥ | ≥ | ≈ | ||

| 201Cu | 0,08 | 1,00 | 7.5-10 | 0,06 | 0,03 | 4.00-6.00 | 14.0-17.0 | 2.0-3.0 | ||

| 201 | 0,15 | 1,00 | 8,50 | 0,06 | 0,03 | 3.50-5.50 | 16.0-18.0 | N≤0.25 | ||

| 130M/202 | 0,15 | 1,00 | 7.5-10 | 0,06 | 0,03 | 4.00-6.00 | 17.0-19.0 | N≤0.25 | ||

| 202 | 0,15 | 1,00 | 7.5-10 | 0,06 | 0,03 | 4.00-6.00 | 17.0-19.0 | |||

| 301 | 0,15 | 1,00 | 2,00 | 0,045 | 0,03 | 5.00-8.00 | 16.0-18.0 | |||

| 302 | 0,15 | 1,00 | 2,00 | 0,045 | 0,03 | 8.00-10.0 | 17.0-19.0 | |||

| XM7 (302HQ) |

0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.50-10.5 | 17.0-9.00 | 3.0-4.0 | ||

| 303 | 0,15 | 1,00 | 2,00 | 0,20 | ≥0.15 | 8.00-10.0 | 17.0-19.0 | ≤0.60 | ||

| 303Cu | 0,15 | 1,00 | 3,00 | 0,20 | ≥0.15 | 8.0-10.0 | 17.0-19.0 | ≤0.60 | 1.5-3.5 | |

| 304 | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.00-10.0 | 18.0-20.0 | |||

| 304H | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.0-10.0 | 18.0-20.0 | |||

| 304HC | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.00-10.0 | 17.0-19.0 | 2.0-3.0 | ||

| 304HCM | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.0-10.0 | 17.0-19.0 | 2.5-4.0 | ||

| 304L | 0,03 | 1,00 | 2,00 | 0,045 | 0,03 | 9.0-13.0 | 18.0-20.0 | |||

| los 304M | 0,06 | 1,00 | 2,00 | 0,045 | 0,03 | 8.50-10.0 | 18.0-20.0 | |||

| 305 | 0,12 | 1,00 | 2,00 | 0,045 | 0,03 | 10.5-13.0 | 17.0-19.0 | |||

| 305J1 | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 11.0-13.5 | 16.5-19.0 | |||

| 309S | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 12.0-15.0 | 22.0-14.0 | |||

| 310S | 0,08 | 1,50 | 2,00 | 0,045 | 0,03 | 19.0-22.0 | 24.0-26.0 | |||

| 314 | 0,25 | 15. - 3,0 | 2,00 | 0,040 | 0,03 | 19,0--22,0 | 24.0-26.0 | |||

| 316 | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | ||

| 316Cu | 0,03 | 1,00 | 2,00 | 0,045 | 0,03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 2.0-3.0 | |

| 316L (12Ni) |

0,03 | 1,00 | 2,00 | 0,045 | 0,03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | ||

| 316L (10Ni) |

0,03 | 1,00 | 2,00 | 0,045 | 0,03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | ||

| 321 | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 9.00-13.0 | 17.0-19.0 | El Ti≤5*C% | ||

| 410 | 0,15 | 1,00 | 0,03 | 11.5-13.5 | ||||||

| 416 | 0,15 | 1,25 | ≥0.15 | 12.0-14.0 | ||||||

| 420 | 0.26-0.4 | 1,00 | 0,03 | 12.0-14.0 | ||||||

| 410L | 0,30 | 1,00 | 1,00 | 0,040 | 0,03 | 11.5-13.5 | ||||

| 430 | 0,12 | 0,75 | 1,00 | 0,040 | 0,03 | 16.0-18.0 | ||||

| 430F | 0,12 | 1,00 | 1,25 | 0,060 | 0,15 | 16.0-18.0 | ||||

| 631 (J1) | 0,09 | 1,00 | 1,00 | 0,040 | 0,03 | 6.50-8.50 | 16.0-18.0 | AL 0.75-1.5 | ||

| 2520 | 0,08 | 1,00 | 2,00 | 0,035 | 0,03 | 19.0-22.0 | 24.0-26.0 | |||

| 410 | 0,015 | 1,00 | 1,00 | 0,04 | 0,03 | 11.5-13.5 | |

|||

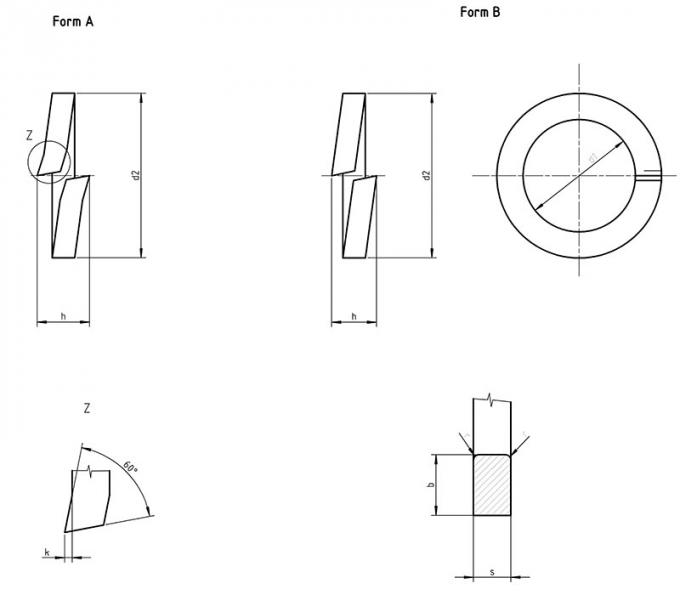

d1 - diámetro interno

d2 - diámetro externo

S - anchura de la lavadora

h - altura descargada de la lavadora

r - radio

longitud del lado b

Acero: acero de la primavera

Inoxidable: A2, A4

Plástico: -

No ferroso: -

Hilo: -

Notas:

-

|

|

| Cuota De Producción: | 500kg |

| Precio: | Negotiation |

| Embalaje Estándar: | 25kg Carton+900kg/Pallet o 5KG/CTN |

| Período De Entrega: | 15days |

| Forma De Pago: | L/C, T/T, OA |

| Capacidad De Suministro: | 200Ton/month |

Cerradura de primavera de DIN127B M2 a las lavadoras de acero inoxidables grandes M100

Pues usted aprieta un perno, estas lavadoras métricas aplanan para añadir la tensión a la junta roscada y para evitar el aflojamiento de pequeñas cantidades de vibración. Todas estas lavadoras cumplen un estándar del estruendo o de ASME para las dimensiones partidas de la lavadora de cerradura.

Las lavadoras de cerradura partidas estándar tienen una hélice izquierda, que los medios usted pueden solamente utilizarlas con los pernos que tienen hilos derechos para prevenir la rotación a la derecha de la vibración. Cuando está apretado, su mordedura desigual de los extremos de fractura en nueces sin templar - y - pernos para un control más apretado que lavadoras curvado o de la onda, pero solamente para los usos con la rotación a la derecha. Las lavadoras, nueces, y los pernos serán deformados cuando están aflojados, así que ningunas de ellos pueden ser reutilizadas. No utilice estas lavadoras en superficies endurecidas.

Las lavadoras de acero inoxidables son más resistentes a la corrosión que de acero, y casi como fuertes. 18- 8 lavadoras de acero inoxidables son buenas para los ambientes húmedos, húmedos, y del baldeo, pero corroerán cuando están expuestas al agua salada y a otras soluciones del cloro. 316 lavadoras de acero inoxidables tienen la mejor resistencia a la corrosión. Hacen frente a ambientes mojados, apenas como 18-8 lavadoras de acero inoxidables, pero a diferencia del acero inoxidable 18-8, resisten la corrosión causada por el agua salada, las soluciones del cloro, y las sustancias químicas.

Utilice las lavadoras de acero cinc-plateadas cinc-plateadas y amarillas en sobre todo ambientes secos. La galjanoplastia del cinc ofrece la protección temporal del moho, pero una vez que lleva lejos el acero moho. Todas estas lavadoras son más fuertes y más desgaste - resistentes que el acero inoxidable.

Las lavadoras de acero son más fuertes y más desgaste - resistentes que el acero cinc-plateado y el acero inoxidable. Utilícelas en ambientes secos porque moho en ambientes mojados y corrosivos.

Materiales y compstition químico

| 化学成分 COMPOSI QUÍMICO (%) | ||||||||||

| Tipo | 碳 de C | 硅 del Si | 锰 del manganeso | 磷 de P | 硫 de S | 镍 del Ni | 铬 del Cr | 钼 del MES | 铜 del Cu | Otros |

| ≤ | ≤ | ≤ | ≤ | ≤ | ≥ | ≥ | ≥ | ≈ | ||

| 201Cu | 0,08 | 1,00 | 7.5-10 | 0,06 | 0,03 | 4.00-6.00 | 14.0-17.0 | 2.0-3.0 | ||

| 201 | 0,15 | 1,00 | 8,50 | 0,06 | 0,03 | 3.50-5.50 | 16.0-18.0 | N≤0.25 | ||

| 130M/202 | 0,15 | 1,00 | 7.5-10 | 0,06 | 0,03 | 4.00-6.00 | 17.0-19.0 | N≤0.25 | ||

| 202 | 0,15 | 1,00 | 7.5-10 | 0,06 | 0,03 | 4.00-6.00 | 17.0-19.0 | |||

| 301 | 0,15 | 1,00 | 2,00 | 0,045 | 0,03 | 5.00-8.00 | 16.0-18.0 | |||

| 302 | 0,15 | 1,00 | 2,00 | 0,045 | 0,03 | 8.00-10.0 | 17.0-19.0 | |||

| XM7 (302HQ) |

0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.50-10.5 | 17.0-9.00 | 3.0-4.0 | ||

| 303 | 0,15 | 1,00 | 2,00 | 0,20 | ≥0.15 | 8.00-10.0 | 17.0-19.0 | ≤0.60 | ||

| 303Cu | 0,15 | 1,00 | 3,00 | 0,20 | ≥0.15 | 8.0-10.0 | 17.0-19.0 | ≤0.60 | 1.5-3.5 | |

| 304 | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.00-10.0 | 18.0-20.0 | |||

| 304H | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.0-10.0 | 18.0-20.0 | |||

| 304HC | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.00-10.0 | 17.0-19.0 | 2.0-3.0 | ||

| 304HCM | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 8.0-10.0 | 17.0-19.0 | 2.5-4.0 | ||

| 304L | 0,03 | 1,00 | 2,00 | 0,045 | 0,03 | 9.0-13.0 | 18.0-20.0 | |||

| los 304M | 0,06 | 1,00 | 2,00 | 0,045 | 0,03 | 8.50-10.0 | 18.0-20.0 | |||

| 305 | 0,12 | 1,00 | 2,00 | 0,045 | 0,03 | 10.5-13.0 | 17.0-19.0 | |||

| 305J1 | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 11.0-13.5 | 16.5-19.0 | |||

| 309S | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 12.0-15.0 | 22.0-14.0 | |||

| 310S | 0,08 | 1,50 | 2,00 | 0,045 | 0,03 | 19.0-22.0 | 24.0-26.0 | |||

| 314 | 0,25 | 15. - 3,0 | 2,00 | 0,040 | 0,03 | 19,0--22,0 | 24.0-26.0 | |||

| 316 | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | ||

| 316Cu | 0,03 | 1,00 | 2,00 | 0,045 | 0,03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | 2.0-3.0 | |

| 316L (12Ni) |

0,03 | 1,00 | 2,00 | 0,045 | 0,03 | 12.0-15.0 | 16.0-18.0 | 2.0-3.0 | ||

| 316L (10Ni) |

0,03 | 1,00 | 2,00 | 0,045 | 0,03 | 10.0-14.0 | 16.0-18.0 | 2.0-3.0 | ||

| 321 | 0,08 | 1,00 | 2,00 | 0,045 | 0,03 | 9.00-13.0 | 17.0-19.0 | El Ti≤5*C% | ||

| 410 | 0,15 | 1,00 | 0,03 | 11.5-13.5 | ||||||

| 416 | 0,15 | 1,25 | ≥0.15 | 12.0-14.0 | ||||||

| 420 | 0.26-0.4 | 1,00 | 0,03 | 12.0-14.0 | ||||||

| 410L | 0,30 | 1,00 | 1,00 | 0,040 | 0,03 | 11.5-13.5 | ||||

| 430 | 0,12 | 0,75 | 1,00 | 0,040 | 0,03 | 16.0-18.0 | ||||

| 430F | 0,12 | 1,00 | 1,25 | 0,060 | 0,15 | 16.0-18.0 | ||||

| 631 (J1) | 0,09 | 1,00 | 1,00 | 0,040 | 0,03 | 6.50-8.50 | 16.0-18.0 | AL 0.75-1.5 | ||

| 2520 | 0,08 | 1,00 | 2,00 | 0,035 | 0,03 | 19.0-22.0 | 24.0-26.0 | |||

| 410 | 0,015 | 1,00 | 1,00 | 0,04 | 0,03 | 11.5-13.5 | |

|||

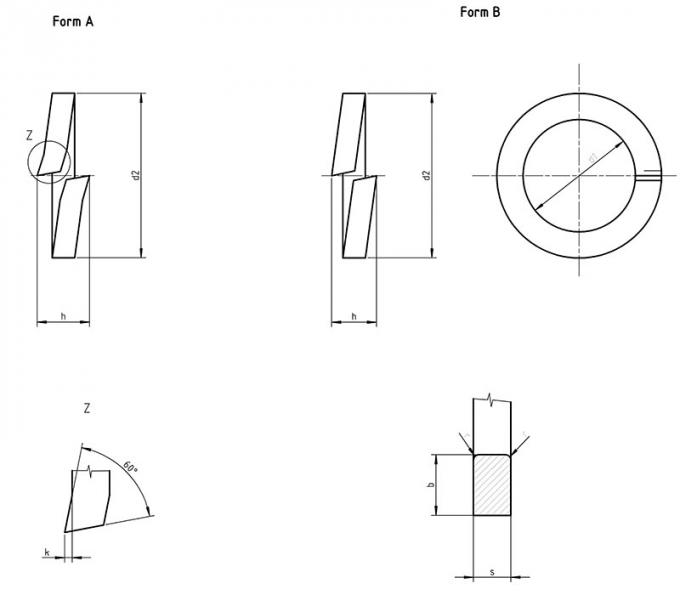

d1 - diámetro interno

d2 - diámetro externo

S - anchura de la lavadora

h - altura descargada de la lavadora

r - radio

longitud del lado b

Acero: acero de la primavera

Inoxidable: A2, A4

Plástico: -

No ferroso: -

Hilo: -

Notas:

-